|

| December 12, 2023 | Volume 19 Issue 46 |

Mechanical News & Products

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

New 'breathable' rupture disk tech provides overpressure and vacuum relief

To increase equipment safety and reliability, a new rupture disk technology activates at a set burst pressure, but it can also "breathe" to relieve minor pressure fluctuations. The patent-pending, dual-function device from BS&B Safety Systems is ideal for use on low-pressure vessels that are susceptible to ambient temperature changes.

To increase equipment safety and reliability, a new rupture disk technology activates at a set burst pressure, but it can also "breathe" to relieve minor pressure fluctuations. The patent-pending, dual-function device from BS&B Safety Systems is ideal for use on low-pressure vessels that are susceptible to ambient temperature changes.

Read the full article.

Engineer's Toolbox: 9 considerations for specifying a slewing ring bearing

In applications that require a bearing to support a structure while it rotates (e.g., cranes, radar, tank turrets), premature bearing failure can put people and equipment at risk. While slewing ring bearings have proven themselves countless times in such applications, designers must consider many factors when specifying them. According to engineers at Kaydon, the bearing's support structure, mounting (including bolt strength, tensioning, and hole patterns), installation, and even storage are all factors in a bearing's success or failure.

In applications that require a bearing to support a structure while it rotates (e.g., cranes, radar, tank turrets), premature bearing failure can put people and equipment at risk. While slewing ring bearings have proven themselves countless times in such applications, designers must consider many factors when specifying them. According to engineers at Kaydon, the bearing's support structure, mounting (including bolt strength, tensioning, and hole patterns), installation, and even storage are all factors in a bearing's success or failure.

Read the full article.

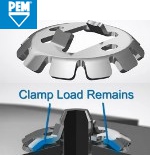

ClampDisk micro fastener is new alternative for automotive and consumer electronics

Designed as a unique alternative in assemblies for the automotive and consumer electronics markets, the ClampDisk Press-on Fastener is a new offering from PennEngineering that delivers a fast, simple way to achieve sheet-to-sheet clamped fastening while replacing the use of standard screws, nuts, and adhesives. The most common challenges that can be eliminated or reduced by using ClampDisk include over installation, cross threading, stripped screw heads, broken screws, and damaged product. This fastener can be removed easily with a sharp-edged tool.

Designed as a unique alternative in assemblies for the automotive and consumer electronics markets, the ClampDisk Press-on Fastener is a new offering from PennEngineering that delivers a fast, simple way to achieve sheet-to-sheet clamped fastening while replacing the use of standard screws, nuts, and adhesives. The most common challenges that can be eliminated or reduced by using ClampDisk include over installation, cross threading, stripped screw heads, broken screws, and damaged product. This fastener can be removed easily with a sharp-edged tool.

Learn more and see how ClampDisk works.

New nylon constant torque hinge

Southco has expanded its line of E6 Constant Torque Hinges with a compact, nylon version designed for small applications. The newest addition to the company's E6 50 Constant Torque Position Control Hinge series measures 45 mm with a torque range of 4 to 16 in./lb and is 65% lighter compared to the standard E6 50 Hinge. It provides constant resistance throughout the entire range of motion, enabling users to easily position doors, display screens, and other mounted components and hold them securely at any desired angle.

Southco has expanded its line of E6 Constant Torque Hinges with a compact, nylon version designed for small applications. The newest addition to the company's E6 50 Constant Torque Position Control Hinge series measures 45 mm with a torque range of 4 to 16 in./lb and is 65% lighter compared to the standard E6 50 Hinge. It provides constant resistance throughout the entire range of motion, enabling users to easily position doors, display screens, and other mounted components and hold them securely at any desired angle.

Learn more.

What injection molding material do I use?

How do you decide what type of plastic to use for your next injection molding project? Xometry can help you narrow your choices. Discover the different strengths and applications for materials that could be ideal for your application by learning about the most common plastic injection molding materials in detail.

How do you decide what type of plastic to use for your next injection molding project? Xometry can help you narrow your choices. Discover the different strengths and applications for materials that could be ideal for your application by learning about the most common plastic injection molding materials in detail.

Read this detailed Xometry article.

What are carbon composite bellows springs?

The Carbon Composite Bellows Spring (CCBS) from MW Components is a system of carbon fiber elements that combine to work as a high-performance, lightweight, and design-flexible compression spring meant to replace coil springs or metallic Belleville disc springs. A functional spring is made from several individual elements paired and joined to make a stack. The stack spring rate is determined by the number of elements, the base rate of each element, and their series or parallel orientation in the stack. Applications include motorsports, aerospace, and high-performance activities.

The Carbon Composite Bellows Spring (CCBS) from MW Components is a system of carbon fiber elements that combine to work as a high-performance, lightweight, and design-flexible compression spring meant to replace coil springs or metallic Belleville disc springs. A functional spring is made from several individual elements paired and joined to make a stack. The stack spring rate is determined by the number of elements, the base rate of each element, and their series or parallel orientation in the stack. Applications include motorsports, aerospace, and high-performance activities.

Learn more.

Conductive Brush Ring overcomes current leakage in EV powertrains

SKF's new Conductive Brush Ring paves the way to greater reliability and longer life in high-performance electric vehicle powertrain systems. Using pure carbon fiber bristles, it provides a reliable electrical connection between an EV eAxle rotor shaft and its housing. When used in combination with SKF Hybrid ceramic ball bearings, it helps to alleviate parasitic current effects that can lead to premature failure in bearings and other components. Available in different configurations for wet (oil-lubricated) motor designs -- and soon for dry (sealed) applications.

SKF's new Conductive Brush Ring paves the way to greater reliability and longer life in high-performance electric vehicle powertrain systems. Using pure carbon fiber bristles, it provides a reliable electrical connection between an EV eAxle rotor shaft and its housing. When used in combination with SKF Hybrid ceramic ball bearings, it helps to alleviate parasitic current effects that can lead to premature failure in bearings and other components. Available in different configurations for wet (oil-lubricated) motor designs -- and soon for dry (sealed) applications.

Learn more.

hyperMILL 2024 CAD/CAM software suite

OPEN MIND Technologies has introduced its latest hyperMILL 2024 CAD/CAM software suite, which includes a range of powerful enhancements to its core toolpath capabilities, as well as new functionality for increased NC programming efficiency in applications ranging from 2.5D machining to 5-axis milling. New and enhanced capabilities include: Optimized Deep Hole Drilling, a new algorithm for 3- and 5-axis Rest Machining, an enhanced path layout for the 3D Plane Machining cycle, better error detection, and much more.

OPEN MIND Technologies has introduced its latest hyperMILL 2024 CAD/CAM software suite, which includes a range of powerful enhancements to its core toolpath capabilities, as well as new functionality for increased NC programming efficiency in applications ranging from 2.5D machining to 5-axis milling. New and enhanced capabilities include: Optimized Deep Hole Drilling, a new algorithm for 3- and 5-axis Rest Machining, an enhanced path layout for the 3D Plane Machining cycle, better error detection, and much more.

Learn more.

One-part epoxy changes from red to clear under UV

Master Bond UV15RCL is a low-viscosity, cationic-type UV-curing system with a special color-changing feature. The red material changes to clear once exposed to UV light, indicating that there is UV light access across the adhesive material. Although this change in color from red to clear does not indicate a full cure, it does confirm that the UV light has reached the polymer. This epoxy is an excellent electrical insulator. UV15RCL adheres well to metals, glass, ceramics, and many plastics, including acrylics and polycarbonates.

Master Bond UV15RCL is a low-viscosity, cationic-type UV-curing system with a special color-changing feature. The red material changes to clear once exposed to UV light, indicating that there is UV light access across the adhesive material. Although this change in color from red to clear does not indicate a full cure, it does confirm that the UV light has reached the polymer. This epoxy is an excellent electrical insulator. UV15RCL adheres well to metals, glass, ceramics, and many plastics, including acrylics and polycarbonates.

Learn more.

SPIROL Press-N-Lok™ Pin for plastic housings

The Press-N-Lok™ Pin was designed to permanently retain two plastic components to each other. As the pin is inserted, the plastic backfills into the area around the two opposing barbs, resulting in maximum retention. Assembly time is quicker, and it requires lower assembly equipment costs compared to screws and adhesives -- just Press-N-Lok™!

The Press-N-Lok™ Pin was designed to permanently retain two plastic components to each other. As the pin is inserted, the plastic backfills into the area around the two opposing barbs, resulting in maximum retention. Assembly time is quicker, and it requires lower assembly equipment costs compared to screws and adhesives -- just Press-N-Lok™!

Learn more about the new Press-N-Lok™ Pin.

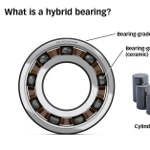

Why hybrid bearings are becoming the new industry standard

A combination of steel outer and inner rings with ceramic balls or rollers is giving hybrid bearings unique properties, making them suitable for use in a wide range of modern applications. SKF hybrid bearings make use of silicon nitride (twice as hard as bearing steel) rolling elements and are available as ball bearings, cylindrical roller bearings, and in custom designs. From electric erosion prevention to friction reduction and extended maintenance intervals, learn all about next-gen hybrid bearings.

A combination of steel outer and inner rings with ceramic balls or rollers is giving hybrid bearings unique properties, making them suitable for use in a wide range of modern applications. SKF hybrid bearings make use of silicon nitride (twice as hard as bearing steel) rolling elements and are available as ball bearings, cylindrical roller bearings, and in custom designs. From electric erosion prevention to friction reduction and extended maintenance intervals, learn all about next-gen hybrid bearings.

Read the SKF technical article.

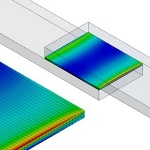

3M and Ansys train engineers on simulating adhesives

Ansys and 3M have created an advanced simulation training program enabling engineers to enhance the design and sustainability of their products when using tapes and adhesives as part of the design. Simulation enables engineers to validate engineering decisions when analyzing advanced polymeric materials -- especially when bonding components made of different materials. Understand the behavior of adhesives under real-world conditions for accurate modeling and design.

Ansys and 3M have created an advanced simulation training program enabling engineers to enhance the design and sustainability of their products when using tapes and adhesives as part of the design. Simulation enables engineers to validate engineering decisions when analyzing advanced polymeric materials -- especially when bonding components made of different materials. Understand the behavior of adhesives under real-world conditions for accurate modeling and design.

Read this informative Ansys blog.

New FATH T-slotted rail components in black from AutomationDirect

Automation-Direct has added a wide assortment of black-colored FATH T-slotted hardware components to match their SureFrame black anodized T-slotted rails, including: cube connectors (2D and 3D) and angle connectors, joining plates of many types, brackets, and pivot joints. Also included are foot consoles, linear bearings in silver and black, cam lever brakes, and L-handle brakes. FATH T-slotted hardware components are easy to install, allow for numerous T-slotted structure configurations, and have a 1-year warranty against defects.

Automation-Direct has added a wide assortment of black-colored FATH T-slotted hardware components to match their SureFrame black anodized T-slotted rails, including: cube connectors (2D and 3D) and angle connectors, joining plates of many types, brackets, and pivot joints. Also included are foot consoles, linear bearings in silver and black, cam lever brakes, and L-handle brakes. FATH T-slotted hardware components are easy to install, allow for numerous T-slotted structure configurations, and have a 1-year warranty against defects.

Learn more.

Weird stuff: Moon dust simulant for 3D printing

Crafted from a lunar regolith simulant, Basalt Moon Dust Filamet™ (not a typo) available from The Virtual Foundry closely mirrors the makeup of lunar regolith found in mare regions of the Moon. It enables users with standard fused filament fabrication (FFF) 3D printers to print with unparalleled realism. Try out your ideas before you go for that big space contract, or help your kid get an A on that special science project.

Crafted from a lunar regolith simulant, Basalt Moon Dust Filamet™ (not a typo) available from The Virtual Foundry closely mirrors the makeup of lunar regolith found in mare regions of the Moon. It enables users with standard fused filament fabrication (FFF) 3D printers to print with unparalleled realism. Try out your ideas before you go for that big space contract, or help your kid get an A on that special science project.

Learn more.

Break the mold with custom injection molding by Rogan

With 90 years of industry experience, Rogan Corporation possesses the expertise to deliver custom injection molding solutions that set businesses apart. As a low-cost, high-volume solution, injection molding is the most widely used plastics manufacturing process. Rogan processes include single-shot, two-shot, overmolding, and assembly. Elevate your parts with secondary operations: drilling and tapping, hot stamping, special finishes, punch press, gluing, painting, and more.

With 90 years of industry experience, Rogan Corporation possesses the expertise to deliver custom injection molding solutions that set businesses apart. As a low-cost, high-volume solution, injection molding is the most widely used plastics manufacturing process. Rogan processes include single-shot, two-shot, overmolding, and assembly. Elevate your parts with secondary operations: drilling and tapping, hot stamping, special finishes, punch press, gluing, painting, and more.

Learn more.

Navy pilots can now train for hypoxia, hyperoxia, and excessive breathing pressures safely

A U.S. Navy aviator receives training on the TS-872 Breathing Dynamics Trainer at the Naval Survival Training Institute in Orlando, FL. The TS-872 allows aviators to experience the effects of breathing issues in a safe training environment, such as hyperoxia (too much oxygen) and excessive inhalation/exhalation pressures.

By Rebecca Ward, Office of Naval Research

A TechSolutions-sponsored project has been honored with an award from the National Training and Simulation Association (NTSA) for its TS-872 Breathing Dynamics Trainer, created in a collaboration with the Naval Aviation Training Systems and Ranges Program Office at Naval Air Systems Command (NAVAIR PMA-205) and the Naval Medical Research Center (NMRC).

TechSolutions is a department within the Office of Naval Research (ONR) Global, which quickly responds to viable requests for new or improved technologies or systems from Sailors and Marines. In the case of the Breathing Dynamics Trainer, Jason Payne, director, TechSolutions, said there was already training for pilots to experience hypoxia (low oxygen) using the Mask on Breathing Device (MOBD). However, TechSolutions received a request to expand its capabilities so that pilots could experience the effects of other breathing issues in a safe training environment, such as hyperoxia (too much oxygen) and excessive inhalation/exhalation pressures.

"There's other physiological conditions that can be experienced based on the gas inhaled and exhaled, its content, the pressure at which it's made available, and the pressure at which you exhale into the mask," Payne said. "Our developers added new profiles to the trainer so that aviators could experience, in the classroom, conditions thought to be associated with physiological episodes that were leading to catastrophes."

The Dynamic Altitude Breathing Threats Research and Development Team includes Principal Investigator Beth Wheeler Atkinson, a senior research psychologist with the Basic and Applied Training and Technologies for Learning and Evaluation (BATTLE) lab, who thanked the team for their achievement.

"It took everyone's skills, expertise, and hands to accomplish this effort successfully. I truly appreciate the effort and contributions you each made to working this challenge for the aviation survival training community," Atkinson said.

Along with Atkinson, the development team for the Breathing Dynamics Trainer included Mitchell Tindall, Naval Air Warfare Center Training Systems Division (NAWCTSD); Emily Anania, NAWCTSD; Kylie Fernandez-Lee, NAWCTSD; Cdr. Heath Clifford, Navy Medicine Operational Training Command (NMOTC); Lt. Alicia Jordan, Aeromedical Safety Office, Marine Aircraft Group 31; Lt. James Lewis, Training Air Wing Six (CTW-6); and Lt. Tyler Welden, Training Air Wing Five (CTW-5).

The Breathing Dynamics Trainer won the 2023 NTSA Modeling and Simulation award in the Education and Human Performance award category, which was presented at a ceremony Nov. 28, 2023, during the Interservice Industry Training Simulation and Education Conference in Orlando, FL.

"This illustrates what can be accomplished through our Sailors and Marines who see the problems firsthand and help us come up with solutions," Payne said.

"The development team took an idea and ran with it," Payne added, "but it began with an idea from a Sailor in the aviation training community who recognized an issue and asked us to help develop a solution. This is exactly why TechSolutions was created, and so we encourage Navy and Marine personnel, no matter their rank or occupation, to contact us about their challenges that may be solved with new or improved technology."

Published December 2023

Rate this article

View our terms of use and privacy policy